Phospating Barrels

Comprehensive Barrel Line

Auto Door Barrel

Our comprehensive barrel line allows you the flexibility to put together the combination of cylinder style, construction method and superstructure configuration that best suits your application.

Configuration Options

CYLINDER STYLES

Round or Hexagonal

MOTORS

Available as fixed or variable speed, air or electric, in either an Overhead Motor Control or Side Drive style

PERFORATIONS

Four standard sizes; 3/32”, 5/32”, 1/8”, and 3/16” are offered, others available on request

DRIVE TRAIN

Gear (metal or plastic), or Chain

MATERIALS

Mild Steel, T-316 stainless steel, T-304 stainless steel, 20 Cb-3, Monel, Inconel

SUPERSTRUCTURE FRAMES

Three basic hangerarm arrangements are available with or without automatic pickups.

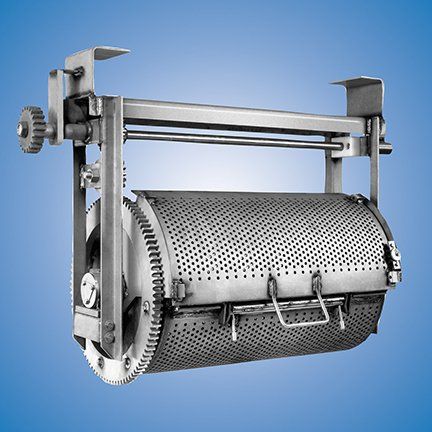

Phospating Barrels...

Using only heavy gauge material and high strength non-corrosive bearings, Hardwood Line, in conjunction with our partners, has engineered a line of rugged, long life, metal barrels. Designed to withstand the acidic/caustic environment of todays metal finishing shop, Hardwood Line’s metal barrels provide maximum durability with minimal maintenance.

All Hardwood Line metal barrels are, in conjunction with our partners, custom manufactured to your requirements. Our Technical Support Department will be happy to assist you in determining the design that will best suit your application and insure that you will receive a barrel that will maximize the efficiency of your operation in the most cost effective way possible.

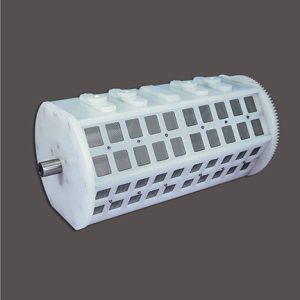

PolyMetal™ Phosphating Cylinders

The PolyMetal cylinder, comprised of a polypropylene shell, features easily replaceable metal panels. The metal panels, perforated to your specifications, are available in a wide range of materials such as steel, 304, 316, C-20SS, Inconel or Monel.

The PolyMetal cylinder can be manufactured to your specifications to any size hex diameter. It can also be adapted to fit all existing superstructure configurations. All PolyMetal cylinders come equipped with Hardwood Line’s patented I/O door with either a turn screw or spring loaded cross bar fasteners.